Call: 08045815186

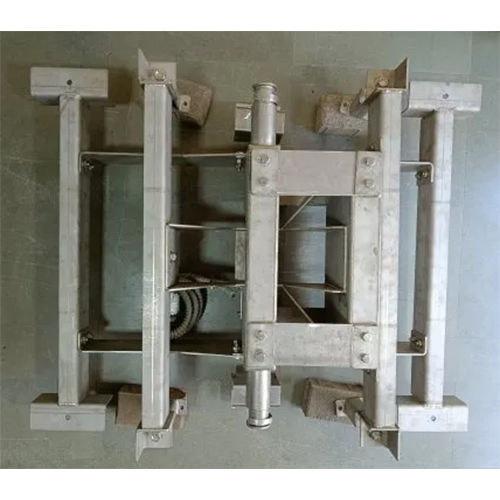

Conveyor Belt Weight Scale

Price 275000 INR/ Unit

MOQ : 1 Unit

Conveyor Belt Weight Scale Specification

- Accuracy

- High precision, typical error 0.5%

- Connection

- Digital display and analog output, RS485/RS232 compatible

- Pressure

- Designed to withstand typical industrial operating pressures

- Function

- Measures and records the weight of materials on a moving conveyor belt

- Load Cell Type

- Strain gauge-based load cells

- Mounting Type

- Belt-mounted

- Display Type

- Digital/LED

- Application

- Bulk material handling, mining, cement, aggregates, food processing

- Belt Width Compatibility

- Custom-fit to client specifications

- Data Output

- 4-20mA, RS232/RS485, Ethernet option

- Calibration

- Factory calibrated, on-site recalibration supported

- Weighing Capacity

- Customizable as per application

- Power Supply

- 220V AC / Custom options

- Operating Temperature

- -10°C to +60°C

Conveyor Belt Weight Scale Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

- Main Domestic Market

- All India

About Conveyor Belt Weight Scale

Streamline your material handling with our Conveyor Belt Weight Scale. Engineered for accuracy, this scale seamlessly integrates into conveyor systems, offering precise weight measurements of transported materials. With a durable design and advanced technology, it ensures reliable performance in diverse industrial applications. The user-friendly interface and easy calibration make it a practical choice for monitoring and optimizing production processes. Upgrade your conveyor system with our Conveyor Belt Weight Scale to enhance efficiency, quality control, and overall productivity in material handling operations.

Versatile Application & Precision Engineering

Designed for diverse industries, including mining, cement, and food processing, this belt-mounted scale provides unmatched precision in measuring and recording material weight. Its high accuracy and robust design ensure consistent performance for bulk handling operations, optimizing process efficiency and reducing operational costs.

Comprehensive Connectivity and Adaptability

Featuring a digital LED display, analog 4-20mA output, and communication options like RS232, RS485, and Ethernet, this system integrates seamlessly with industrial control networks. Its customizable size and belt width compatibility allow straightforward adaptation to client-specific requirements, supporting diverse installation scenarios.

FAQs of Conveyor Belt Weight Scale:

Q: How is the Conveyor Belt Weight Scale installed on an existing conveyor system?

A: The scale is mounted directly onto your existing conveyor structure and tailored to match custom belt widths. Installation is performed by qualified technicians, ensuring integration with your current setup and minimal disruption to operations.Q: What benefits does this digital/LED conveyor scale offer for bulk material handling?

A: This scale delivers real-time, accurate measurement of material flow, helping operators monitor production efficiency, reduce losses, and maintain quality control. Its high precision ensures reliable data for process optimization.Q: When should the system be recalibrated?

A: Although the scale is factory calibrated, it is advisable to recalibrate periodically or after significant maintenance events. On-site recalibration is supported, ensuring sustained measurement accuracy.Q: Where can this conveyor scale be used?

A: It is suitable for a range of industrial settings, including mining operations, cement plants, aggregate processing facilities, and food production units across India and beyond. Its rugged design withstands industrial pressures and temperatures from -10C to +60C.Q: What is the process for data output and integration with plant systems?

A: The system offers data output via analog (4-20mA) and digital (RS232/RS485, Ethernet) interfaces, making integration with plant automation and SCADA systems straightforward. This supports remote monitoring and data logging for enhanced process control.Q: How does the strain gauge-based load cell ensure high accuracy?

A: Strain gauge load cells transform mechanical load into precise electrical signals, providing high-resolution weight measurements with an error margin of 0.5%. This ensures dependable and consistent results in demanding industrial environments.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry